High Alumina Refractory Castable

Bayanin samfur

| Sunan samfur | Refractory Castable |

| Categories | Ƙarƙashin Siminti Castable/Maɗaukakin Ƙarfin Castable/Babban Alumina Castable/Maɗaukaki Castable |

| Abun ciki | Abubuwan da aka haɗa, foda da masu ɗaure |

| Siffofin | 1.Sauƙin Gina, 2.Good Slag Resistance, 3. Kyakkyawan juriya na lalata, 4.Good Wuta Resistance, 5.Tsarin Makamashi Da Kare Muhalli. |

| Aikace-aikace | Ana Amfani da Yadu A cikin Tanderun Masana'antu Masu Zazzabi Daban-daban. |

| Kayayyaki | Low Cement Castable | Ƙarfafa Castable |

| Bayani | Ƙananan simintin siminti na nufin sabbin siminti masu ƙaramin ɗauren siminti.Abubuwan da ke cikin siminti na simintin gyaran fuska gabaɗaya ya kai kashi 15% zuwa 20%, kuma abun cikin siminti na ƙananan simintin siminti kusan kashi 5% ne, wasu ma an rage su zuwa 1% zuwa 2%. | Ƙarfin lalacewa mai jurewa simintin gyare-gyare ya ƙunshi babban ƙarfin tarawa, abubuwan haɗin ma'adinai, babban ƙarfin tarawa da maganin fasa da wakili mai jurewa. |

| Siffofin | Juriya na girgiza zafin zafi, juriyar slag, da juriya na yazawa an inganta su sosai, sun zarce tubalin da ke jujjuyawa irin wannan. | Ƙarfin ƙarfi mai ƙarfi, juriya mai ƙarfi, juriya mai tasiri, juriya na yashwa, ƙarancin mai, sarrafa sifar sabani, mutunci mai ƙarfi, gini mai sauƙi, kyakkyawan aikin gini, da dogon sabis. |

| Aikace-aikace | 1.Lining na daban-daban zafi magani tanderu, dumama tanderu, shaft kilns, Rotary kilns, lantarki tanderu cover, fashewa tapholes tapholes; 2.Self-flowing low-ciment castables su dace da high-zazzabi fesa gun linings for SPRAY metallurgy da petrochemical catalytic fatattaka reactors Wear-resistant rufi, m rufi na dumama makera ruwa-sanya bututu, da dai sauransu. | Layer mai jure lalacewa na slag sluice,trough tama, coal spout, hopper da silo in metallurgy, coal, thermal power, chemical,siminti da sauran masana'antu, da kuma fashewa tanderu hadawa silo, sintering silo, feeder, pelletizer, da dai sauransu. |

| Kayayyaki | High Alumina Castable | Castable mai nauyi |

| Bayani | High-alumina castables ne refractorycastables sanya daga high-alumina raw kayana matsayin aggregates da powders, da kuma karatare da ɗaure. | Siminti mai sauƙi tare da ƙananan ƙarancin yawa an yi shi da siminti aluminate, babban kayan alumina mai kyau, ceramsite, da ƙari. |

| Siffofin | Yana da ƙarfin injina mai ƙarfi da juriya mai kyau na thermal, juriya abrasion da sauran kaddarorin. | Ƙarƙashin ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan zafi, kyakkyawan sakamako mai mahimmanci na thermal, ƙarfin matsa lamba, acid da acid gas juriya, zafi mai zafi, zafi mai zafi, da ƙananan ƙarancin ruwa. |

| Aikace-aikace | Ana amfani da shi ne a matsayin rufin ciki na tukunyar jirgi, murhu mai zafi mai zafi, tanderun dumama, yumbun kilns da sauran kilns. | Za'a iya amfani da simintin simintin nauyi mai nauyi don rufin rufin zafi na tanderun masana'antu masu zafi da kayan aiki kuma ana amfani da su don rufin bututun iskar gas mai zafi daban-daban. |

Fihirisar Samfura

Tanderu Mai zafi

Tunnel Kiln

Rotary Kiln

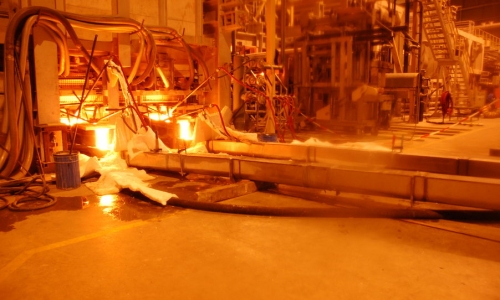

Masana'antar ƙarfe da ƙarfe: galibi ana amfani da su don kulawa da facin murhun wutar lantarki, tanderun ƙarfe, ladles da sauran kayan aiki.

Non-ferrous karfe masana'antu: amfani da faci da kuma gyara na jan karfe, aluminum, zinc, nickel da sauran wadanda ba karfe smelting tanda da converters.

Gilashin masana'antu: ana amfani da su don kulawa da aikin facin gilashin gilashi, murhun murɗa da sauran kayan aiki.

| Sunan samfur | Low Cement Castable | |||||

| INDEX | RBTZJ-42 | RBTZJ-60 | RBTZJ-65 | RBTZJS-65 | RBTZJ-70 | |

| Iyakancin Aiki | 1300 | 1350 | 1400 | 1400 | 1450 | |

| Girman Girma (g/cm3)110 ℃ × 24h ≥ | 2.15 | 2.3 | 2.4 | 2.4 | 2.45 | |

| Ƙarfin Lankwasa Sanyi110 ℃ × 24h (MPa) ≥ | 4 | 5 | 6 | 6 | 7 | |

| Ƙarfin Crushing Cold (MPa) ≥ | 110 ℃ × 24h | 25 | 30 | 35 | 35 | 40 |

| CT ℃ × 3h | 50 1300 ℃ × 3h | 55 1350 ℃ × 3h | 60 1400 ℃ × 3h | 40 1400 ℃ × 3h | 70 1400 ℃ × 3h | |

| Canjin Layi na Dindindin@CT℃×3h(%) | -0.5 ~ + 0.5 1300 ℃ | -0.5 ~ + 0.5 1350 ℃ | 0 ~ + 0.8 1400 ℃ | 0 ~ + 0.8 1400 ℃ | 0 ~ + 1.0 1400 ℃ | |

| Resistance Thermal Shock (1000 ℃ ruwa) ≥ | -- | -- | -- | 20 | -- | |

| Al2O3 (%) ≥ | 42 | 60 | 65 | 65 | 70 | |

| CaO (%) ≤ | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| Fe2O3 (%) ≤ | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Sunan samfur | Ƙarfafa Castable | |||||

| INDEX | HS-50 | HS-60 | HS-70 | HS-80 | HS-90 | |

| Yanayin zafin aiki (℃) | 1400 | 1500 | 1600 | 1700 | 1800 | |

| 110 ℃ Girman Girma (g/cm3) ≥ | 2.15 | 2.30 | 2.40 | 2.50 | 2.90 | |

| Modulus na Rupture (MPa) ≥ | 110 ℃ × 24h | 6 | 8 | 8 | 8.5 | 10 |

| 1100 ℃ × 3h | 8 | 8.5 | 8.5 | 9 | 9.5 | |

| 1400 ℃ × 3h | 8.5 1300 ℃ × 3h | 9 | 9.5 | 10 | 15 | |

| Ƙarfin Crushing Cold (MPa) ≥ | 110 ℃ × 24h | 35 | 40 | 40 | 45 | 60 |

| 1100 ℃ × 3h | 40 | 50 | 45 | 50 | 70 | |

| 1400 ℃ × 3h | 45 1300 ℃ × 3h | 55 | 50 | 55 | 100 | |

| Canjin Layi na Dindindin (%) | 1100 ℃ × 3h | -0.2 | -0.2 | -0.25 | -0.15 | -0.1 |

| 1400 ℃ × 3h | -0.45 1300 ℃ × 3h | -0.4 | -0.3 | -0.3 | -0.1 | |

| Al2O3 (%) ≥ | 48 | 48 | 55 | 65 | 75 | 90 |

| CaO (%) ≤ | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Fe2O3 (%) ≤ | 3.5 | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 |

| Sunan samfur | High Alumina Castable | ||||||

| INDEX | Al2O3 (%) ≥ | CaO (%) ≥ | Refractoriness (℃) | CT℃ × 3h PLC ≤1% | 110 ℃ Bayan bushewa (MPa) | ||

| CCS | MOR | ||||||

| Clay Bonded | NL-45 | 45 | -- | 1700 | 1350 | 8 | 1 |

| NL-60 | 60 | -- | 1720 | 1400 | 9 | 1.5 | |

| NL-70 | 70 | -- | 1760 | 1450 | 10 | 2 | |

| Siminti Bonded | GL-42 | 42 | -- | 1640 | 1350 | 25 | 3.5 |

| GL-50 | 50 | -- | 1660 | 1400 | 30 | 4 | |

| GL-60 | 60 | -- | 1700 | 1400 | 30 | 4 | |

| GL-70 | 70 | -- | 1720 | 1450 | 35 | 5 | |

| GL-85 | 85 | -- | 1780 | 1500 | 35 | 5 | |

| Ƙarƙashin Siminti | DL-60 | 60 | 2.5 | 1740 | 1500 | 30 | 5 |

| DL-80 | 80 | 2.5 | 1780 | 1500 | 40 | 6 | |

| Phosphate an haɗa shi | LL-45 | 45 | -- | 1700 | 1350 | 20 | 3.5 |

| LL-60 | 60 | -- | 1740 | 1450 | 25 | 4 | |

| LL-75 | 75 | -- | 1780 | 1500 | 30 | 5 | |

| Sodium Silicate sun haɗa | BL-40 | 40 | -- | -- | 1000 | 20 | -- |

| Sunan samfur | Castable mai nauyi | ||||||

| Yanayin aiki iyaka | 1100 | 1200 | 1400 | 1500 | 1600 | ||

| 110 ℃ Girman Girma (g/cm3) ≥ | 1.15 | 1.25 | 1.35 | 1.40 | 1.50 | ||

| Modulus na Rupture (MPa) ≥ | 110 ℃ × 24h | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100 ℃ × 3h | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400 ℃ × 3h | -- | -- | 3 | 10.8 | 8.1 | ||

| Ƙarfin Crushing Sanyi (MPa) ≥ | 110 ℃ × 24h | 8 | 8 | 11 | 12 | 10 | |

| 1100 ℃ × 3h | 4 | 4 | 5 | 11 | 10 | ||

| 1400 ℃ × 3h | -- | -- | 15 | 22 | 14 | ||

| Canjin Layi na Dindindin (%) | 1100 ℃ × 3h | -0.65 1000 ℃ × 3h | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400 ℃ × 3h | -- | -- | -0.8 | -0.55 | -0.45 | ||

| Ƙarfafa Ƙarfafawa (W/mk) | 350 ℃ | 0.18 | 0.20 | 0.30 | 0.48 | 0.52 | |

| 700 ℃ | 0.25 | 0.25 | 0.45 | 0.61 | 0.64 | ||

| Al2O3 (%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| Fe2O3 (%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

Aikace-aikace

Kunshin&Warehouse