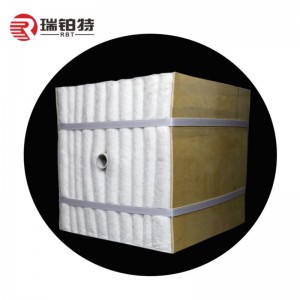

Sassan Siffar Fiber Mai Inganci don Insulation

bayanin

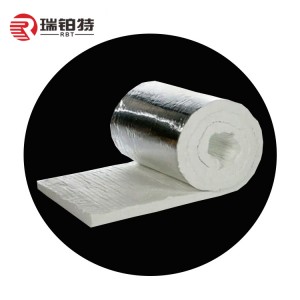

Yin amfani da auduga silicate fiber na aluminium mai inganci azaman albarkatun ƙasa, tsarin gyare-gyaren injin.Yana za a iya sanya a cikin daban-daban girma yawa na 200-400kg / m3, daban-daban siffofi na tubali, allon, kayayyaki, daidaitattun prefabricated sassa, burners, ganguna da sauran musamman kayayyakin ga saduwa da bukatun wasu masana'antu sassa a takamaiman samar links, da kuma ta. siffar da girman buƙatar yin kayan aikin abrasive na musamman.Duk samfuran rashin daidaituwa suna da ƙarancin raguwa akan kewayon zafin sabis ɗin su kuma suna kula da babban rufin zafi, nauyi mai sauƙi da juriya mai tasiri.Ana iya yanke kayan da ba a kone ba cikin sauƙi ko yin injina.A cikin tsarin amfani, samfurin yana da kyawawan kaddarorin rigakafin sawa da ɓacin rai, kuma yawancin narkakkun karafa ba sa lalacewa.

Siffofin

Siffofin samfur: babban rabo na fiber, nauyi mai nauyi, babban ƙarfi, ƙarancin ƙarancin thermal, juriya mai ƙarfi na thermal, injin mai sauƙi, juriya na yashwar iska, sauƙin da ake buƙata don sarrafa yawa, wani matsawa, ƙwanƙwasa, ƙarfin flexural, rikitaccen siffar filastik.

Aikace-aikace

Ana amfani da samfuran a cikin masana'antu daban-daban na kayan aikin thermal kayan zafi mai rufi, goyan baya da rufin zafi, rufin abu na babban zafin jiki na makera bango bango, rataye rufin, anga kofa da tanda, motar kiln, masana'antar sinadarai na mai tare da ƙonawa, abubuwan lura da rami, tsagi, kushin tsagi, ƙaramin baki da tundish, taron hannun rigar riser don narkewar ƙarfe, injiniyan insulation tare da kowane hadadden ginshiƙi.

Fihirisar Samfura

| INDEX \ PRODUCT | STD | HC | HA | HZ |

| Yanayin Rarraba (℃) | 1260 | 1260 | 1360 | 1430 |

| Yanayin Aiki (℃)≤ | 1050 | 1100 | 1200 | 1350 |

| Yawan yawa (kg/m3) | 200-400 | |||

| Ƙarfafa Ƙarfafawa (W/mk) | 0.086 (400 ℃) 0.120 (800 ℃) | 0.086 (400 ℃) 0.110 (800 ℃) | 0.092 (400 ℃) 0.186 (1000 ℃) | 0.092 (400 ℃) 0.186 (1000 ℃) |

| Canjin Layi na Dindindin (%) | -4/1000 ℃ | -3/1100 | -3/1200 | - 3/1350 |

| Modulus na Rupture (MPa) | 6 | |||

| Al2O3 (%) ≥ | 45 | 47 | 55 | 39 |

| Fe2O3 (%) ≤ | 1.0 | 0.2 | 0.2 | 0.2 |

| SiO2 (%) ≤ | 52 | 52 | 49 | 45 |

| ZrO2(%) ≥ | 11-13 | |||