Dubban Tulli

Game da Mullite Bricks

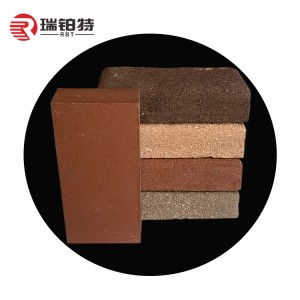

Mullite tubalin su ne babban aluminum refractory tare da mullite a matsayin babban lokaci crystal.Gabaɗaya, abun ciki na alumina yana tsakanin 65% da 75%.Bugu da ƙari ga mullite, ma'adanai tare da ƙananan abun ciki na alumina kuma sun ƙunshi ƙaramin adadin vitreous lokaci da cristobalite.Mafi girman abun ciki na alumina shima ya ƙunshi ƙaramin adadin corundum.

Mullite tubalin suna da babban refractoriness, wanda zai iya kai sama da 1790 ° C.Load softening farkon zafin jiki ne 1600 ℃ 1700 ℃.Ƙarfin matsawa a zafin jiki shine 70-260MPa.Kyakkyawan juriya na girgiza thermal.

Akwai nau'ikan tubalin dunƙule guda biyu da aka haɗa da tubalin dunƙulewa.

An yi bulogin mulli mai ƙwanƙwasa da babban alumina bauxite clinker a matsayin babban kayan albarkatun ƙasa, ƙara ƙaramin yumbu ko ɗanyen bauxite a matsayin ɗaure, kuma ana yin su kuma ana kora su.An yi bulogin mullit ɗin da aka haɗa da babban bauxite, alumina masana'antu da yumbu mai jujjuyawa, kuma ana ƙara gawayi ko coke lafiya barbashi azaman wakili mai ragewa.Bayan gyare-gyare, ana yin su ta hanyar rage electrofusion.

Ƙirƙirar mullite fused ya fi girma fiye da na sintered mullite, kuma juriya na zafin zafi ya fi na samfurori da aka lalata.Babban aikin su na zafin jiki ya dogara ne akan abun ciki na alumina da daidaituwar rarraba lokaci da gilashin.

Ana amfani da bulo mai yawa don saman murhu mai zafi, fashewar tanderu jiki da ƙasa, mai sabunta tanderun gilashi, yumbun kiln, mataccen ruɓi na tsarin fatattakar mai, da sauransu.

Game da Sillimanite

Tubalin sillimanite suna da kwanciyar hankali na zafi mai kyau a babban zafin jiki, juriya ga yashwar ruwan gilashi, ƙananan ƙazanta zuwa ruwan gilashi.

Mafi yawan dacewa da tashar ciyarwa, injin ciyarwa, na'ura mai jan tube da sauran kayan aiki a cikin masana'antar gilashi, wanda zai iya inganta yawan aiki.

Mafi yawan dacewa da tashar ciyarwa, injin ciyarwa, na'ura mai jan tube da sauran kayan aiki a cikin masana'antar gilashi, wanda zai iya inganta yawan aiki.

Fihirisar Samfura

| INDEX | Mullite low sau uku | Sintered mullite | Sillimanite | Fused mullite | ||||

| Saukewa: RBTM-47 | Saukewa: RBTM-65 | Saukewa: RBTM-70 | Saukewa: RBT-M75 | Saukewa: RBTM-80 | Saukewa: RBTA-60 | Saukewa: RBTFM-75 | ||

| Refractoriness (℃) ≥ | 1790 | 1790 | 1790 | 1790 | 1810 | 1790 | 1810 | |

| Girman Girma (g/cm3) ≥ | 2.42 | 2.45 | 2.50 | 2.60 | 2.70 | 2.48 | 2.70 | |

| Bayyanar Ƙarfi (%) ≤ | 12 | 18 | 18 | 17 | 17 | 18 | 16 | |

| Ƙarfin Crushing Cold (MPa) ≥ | 60 | 60 | 70 | 80 | 85 | 65 | 90 | |

| Canjin Layi na Dindindin (%) | 1400°×2h | +0.1 -0.1 |

|

|

|

|

|

|

| 1500°×2h |

| +0.1 -0.4 | +0.1 -0.4 | +0.1 -0.4 | +0.1 -0.4 | +1 -0.2 | ± 0.1 | |

| Refractoriness Karkashin Load @0.2MPa (℃)≥ | 1520 | 1580 | 1600 | 1600 | 1620 | 1600 | 1700 | |

| Ƙididdigar Ƙira @0.2MPa 1200°×2h (%) ≤ | 0.1 | -- | -- | -- | -- | -- | -- | |

| Al2O3 (%) ≥ | 47 | 64 | 68 | 72 | 78 | 60 | 75 | |

| Fe2O3 (%) ≤ | 1.2 | 0.8 | 0.8 | 0.7 | 0.7 | 1.0 | 0.5 | |