Amfanin tubalin carbon na magnesium sune:juriya ga zaizayar ƙasa da kuma juriyar girgizar zafi mai kyau. A da, rashin amfanin tubalin MgO-Cr2O3 da tubalin dolomite shine suna shan abubuwan da ke cikin slag, wanda ke haifar da zubar da ruwa, wanda ke haifar da lalacewa da wuri. Ta hanyar ƙara graphite, tubalin carbon na magnesia ya kawar da wannan gazawar. Siffarsa ita ce slag ɗin yana shiga cikin saman aiki ne kawai, don haka layin amsawar da aka tanada a saman aiki, tsarin ba shi da ɓawon da ya wuce kima kuma yana da tsawon rai.

Yanzu, ban da tubalin carbon na gargajiya na kwalta da kuma magnesia mai ɗaure da resin (gami da tubalin magnesia mai ƙonewa da aka sanya wa mai),Bulogin carbon na Magnesia da ake sayarwa a kasuwa sun haɗa da:

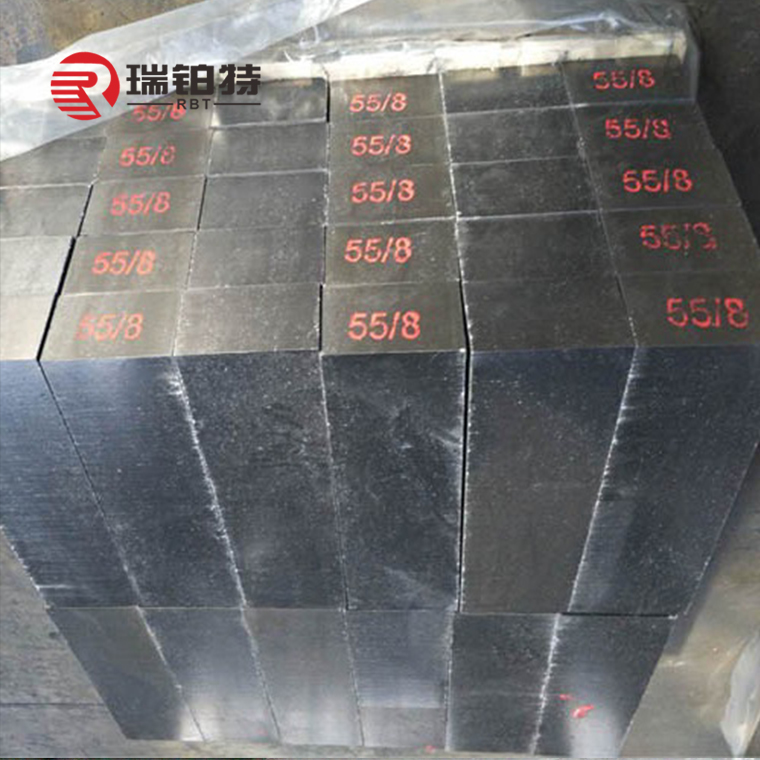

(1) Bulo na carbon na Magnesia da aka yi da magnesia wanda ke ɗauke da 96% ~97% MgO da graphite 94% ~95%C;

(2) Bulo na carbon na Magnesia da aka yi da magnesia wanda ke ɗauke da 97.5% ~ 98.5% MgO da graphite 96% ~ 97% C;

(3) Bulo na carbon na Magnesia da aka yi da magnesia wanda ke ɗauke da 98.5% ~99% MgO da graphite 98% ~C.

Dangane da yawan sinadarin carbon, an raba tubalin carbon na magnesium zuwa:

(I) Bulogin magnesia da aka yi da mai (ƙananan sinadarin carbon ƙasa da 2%);

(2) Bulogin magnesia mai haɗin carbon (ƙarin carbon ƙasa da 7%);

(3) Bulo na carbon da aka haɗa da resin roba (abun da ke cikin carbon shine 8% ~ 20%, har zuwa 25% a wasu lokuta). Sau da yawa ana ƙara antioxidants a cikin bulo na carbon da aka haɗa da kwalta/resin (abun da ke cikin carbon shine 8% zuwa 20%).

Ana samar da tubalin carbon na Magnesia ta hanyar haɗa yashi mai tsafta na MgO tare da scaly graphite, carbon black, da sauransu. Tsarin kera ya haɗa da waɗannan hanyoyin: niƙa kayan da aka ƙera, tantancewa, rarrabawa, haɗawa bisa ga ƙirar kayan aiki da aikin saita samfura, bisa ga haɗin. Zafin nau'in wakili yana ƙaruwa zuwa kusan 100 ~ 200℃, kuma an haɗa shi tare da mai ɗaure don samun abin da ake kira laka MgO-C (haɗen jikin kore). Ana ƙera kayan laka na MgO-C ta amfani da resin roba (galibi resin phenolic) a cikin yanayin sanyi; kayan laka na MgO-C da aka haɗa da kwalta (wanda aka dumama zuwa yanayin ruwa) an ƙera su a cikin yanayin zafi (a kusan 100°C). Dangane da girman rukuni da buƙatun aiki na samfuran MgO-C, ana iya amfani da kayan aikin girgiza na injin, kayan aikin gyaran matsi, extruders, matsi na isostatic, matsi mai zafi, kayan dumama, da kayan aikin ramming don sarrafa kayan laka na MgO-C zuwa siffar da ta dace. An sanya jikin MgO-C da aka samar a cikin murhu a zafin 700 ~ 1200°C don maganin zafi don mayar da sinadarin ɗaurewa zuwa carbon (wannan tsari ana kiransa carbonization). Domin ƙara yawan tubalin carbon na magnesia da kuma ƙarfafa haɗin, ana iya amfani da abubuwan cikawa irin su masu ɗaurewa don sanya tubalin a cikin ruwa.

A zamanin yau, galibi ana amfani da resin roba (musamman resin phenolic) a matsayin wakili mai ɗaure tubalin carbon na magnesia.Amfani da tubalin carbon na roba wanda aka haɗa da resin roba da magnesia yana da fa'idodi masu zuwa:

(1) Bangarorin muhalli suna ba da damar sarrafawa da samar da waɗannan samfuran;

(2) Tsarin samar da kayayyaki a ƙarƙashin yanayin haɗakar sanyi yana adana kuzari;

(3) Ana iya sarrafa samfurin a ƙarƙashin yanayin da ba ya warkarwa;

(4) Idan aka kwatanta da abin ɗaure kwalta, babu wani matakin filastik;

(5) Ƙara yawan sinadarin carbon (ƙarin graphite ko kwal mai siffar bituminous) na iya inganta juriyar lalacewa da juriyar slag.

Lokacin Saƙo: Fabrairu-23-2024